Key Takeaways

1. Zeekr has launched a 1.2 MW rapid EV charger, surpassing BYD’s 1.0 MW charger introduced earlier in March 2025.

2. The new ultra-fast charger will debut at the Shanghai Auto Show in April 2025 and is part of Zeekr’s plan to expand its charging network.

3. Zeekr now holds the title for the fastest EV charger, a title recently held by BYD for a short time.

4. BYD’s Super e-Platform technology can add 400 km of range in just five minutes, and they plan to install 500 fast chargers by April.

5. Tesla’s Superchargers remain popular for their availability, but their charging speed is declining compared to newer competitors, with the latest model providing only 500 kW.

If BYD believed it would bask in the limelight of its EV charger technology for an extended period, Zeekr has other plans. Zeekr has introduced a 1.2 MW rapid EV charger, outpacing BYD’s 1.0 MW charging system that was showcased earlier in March 2025.

Unveiling the New Charger

The ultra-fast charger was presented during VP Zhao Yuhui’s address at the China EV100 Forum. This charger is set to make its first appearance at the Shanghai Auto Show in April 2025. The Chinese company already operates over 4,000 rapid chargers, with a maximum output of 800 kW across 826 stations. The rollout of these new chargers is scheduled for the second quarter of 2025.

A New Record in Charging Speed

Zeekr now holds the title for the fastest EV charger in the world, a title that BYD had for only a few weeks. BYD recently showcased its Super e-Platform charging technology, capable of adding 400 km of range in just five minutes. This was at an event where they also began accepting pre-orders for the Han L sedan and Tang L SUV. BYD aims to install 500 fast chargers by April.

The Status of Tesla’s Superchargers

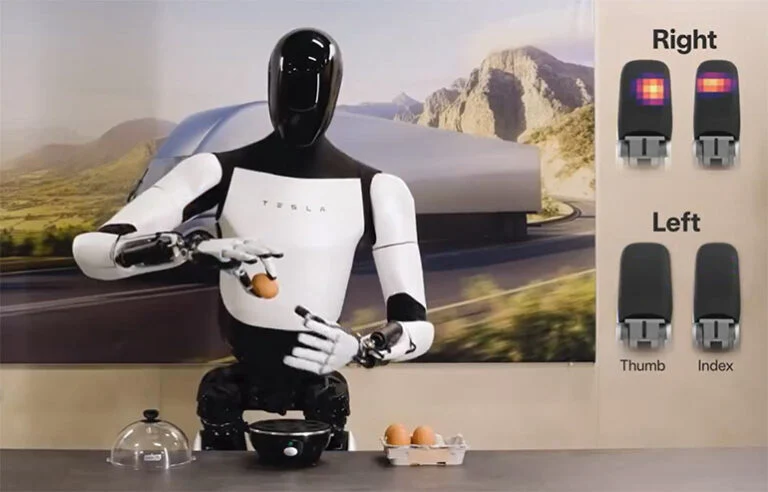

Tesla’s Superchargers remain favored for their widespread availability and dependability. Nevertheless, the American manufacturer is slowly losing its top position in charging speed, as their latest model can only provide 500 kW. Tesla also operates a smaller Megacharger network that can deliver up to 1 MW, but this is reserved for its Class 8 electric Semi trucks in the US.

Source:

Link