Key Takeaways

1. Tesla plans to double US production from about 665,000 vehicles last year to over 1.3 million by 2027.

2. The company currently has the capacity to produce around 1.1 million vehicles annually in the US, needing slight expansion for its new goals.

3. A more affordable vehicle, tentatively called Model 2, is set to be revealed soon, potentially boosting demand.

4. Tesla is enhancing production of the Model Y Juniper refresh and plans facelifts for the Model S and Model X by late 2025.

5. Despite challenges like declining global sales and vandalism, Musk is committed to fulfilling his production goals with upcoming models like the Cybercab.

Tesla is set to increase its production at its US factories by two times over the next two years, according to Elon Musk. This move aligns with the current administration’s push for more goods to be made in America.

Production Goals

This shift means Tesla aims to ramp up its output from around 665,000 vehicles produced in the US last year to over 1.3 million by 2027. Considering Tesla manufactured approximately 1.8 million cars worldwide in 2024, this target for US production alone appears quite ambitious.

Capacity and Demand

At present, Tesla has the capability to produce about 1.1 million vehicles annually in the US, meaning it just needs to slightly expand that capacity. The more challenging aspect will be securing enough American customers for the increased output, a strategy Musk appears to have carefully considered.

New Models on the Horizon

Later this year, Tesla is expected to reveal its most affordable vehicle, tentatively referred to as the Model 2. Elon believes that its lower price could quickly make it a popular choice among buyers. Additionally, the company is gearing up to enhance production of the new Model Y Juniper refresh, which many enthusiasts are eagerly awaiting before making their Tesla purchases.

The Model S and Model X are also set to receive facelifts by late 2025, and Tesla plans to launch a more affordable rear-wheel drive version of the Cybertruck this year, with this model already listed in the IRS tax credit database.

Future Production Plans

The Cybercab, which will use the same production platform as the Model 2, is also scheduled for mass production in 2026. Thus, fulfilling Musk’s commitment to double US production seems achievable, a promise made during an event at the White House.

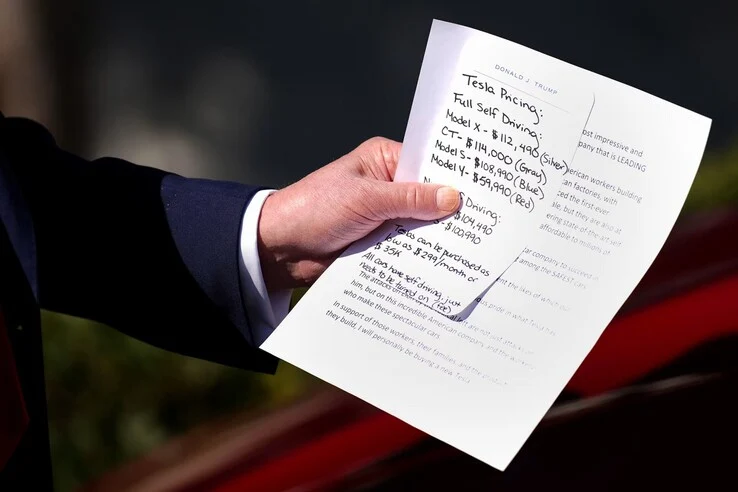

Despite facing difficulties like a dip in global sales and vandalism issues domestically, Elon Musk organized a promotional event at the White House, where he showcased a price list to President Trump and suggested he buy a red Model S Plaid.

Trump expressed his support for Tesla amid the backlash related to Musk’s political activities, which have impacted sales and led to vandalism against Tesla’s Supercharger stations and showrooms. As a gesture of this support, he allowed Musk to bring all Tesla models to the White House and confirmed he would buy a Model S Plaid, which Musk mentioned is his daily driver.

Elon committed to doubling the production of American-made vehicles to around 1.3 million within the next two years, a plan that shouldn’t significantly strain Tesla’s existing budget, as it aligns with prior goals set before the White House endorsement event.

Source:

Link