The findings from a recent study are remarkable and might seem unbelievable. A battery cell made from low-cost materials and requiring only moderate effort shows outstanding performance compared to existing battery technologies. After undergoing 10,000 charging cycles, its capacity remained at an impressive 99% of its initial value. The efficiency of this new battery stayed above 99% consistently, though lithium-ion batteries still have a slight edge in this area. Nevertheless, this innovative solid-state battery excels in stability and durability, making it a strong contender.

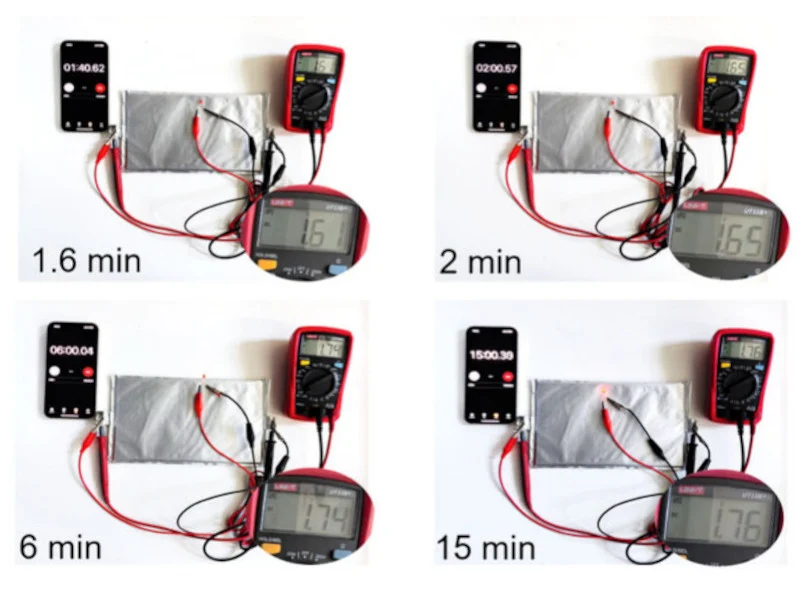

Remarkable Testing Outcomes

The new battery also demonstrated impressive resilience in various tests. Researchers conducted extreme tests where they punctured, short-circuited, and heated the battery cell to 1,000°C. Remarkably, it did not leak or catch fire, and at 200°C, it maintained the same voltage as it did at room temperature. These results highlight the battery’s robustness under challenging conditions.

Breakthrough in Technology

This advancement comes from an aluminum-ion battery using a liquid electrolyte made of aluminum chloride, which usually deteriorates quickly in tests. The anode typically suffers damage, leading to rapid aging of the battery cells. However, by adding aluminum fluoride and coating the electrode with a unique salt, researchers successfully converted the cell into a solid-state battery, addressing the corrosion issue. Together, these components provide high operational safety and outstanding longevity.

The team of researchers from Peking University and the Beijing Institute of Technology also underscored the battery’s recyclability. Aluminum fluoride can be almost entirely washed out and reused for new battery production. Moreover, aluminum itself is highly recyclable, adding to the environmental benefits of this technology.

Energy Density Challenges

However, one significant drawback of this aluminum-based battery is its energy density, which is about 150 watt-hours per kilogram. This is notably lower than that of other competing technologies, being only one-third to one-fifth of the best solid-state and Li-ion batteries. Still, it fares well when compared to standard household batteries.

Given these factors, it appears that these long-lasting and potentially affordable aluminum-ion solid-state batteries will mainly find applications in stationary devices. While there is definite demand for such products, it remains unclear if commercial production will be successful. The battery’s technical features are certainly appealing and worth paying attention too.

Source:

Link