Key Takeaways

1. Elon Musk removed key personnel involved in Tesla’s 4680 battery production, considering sourcing from suppliers if cost reductions weren’t met by year’s end.

2. Tesla has developed a dry cathode production method for the 4680 battery, making it more competitive and integrating it into the Cybertruck.

3. CATL’s chairman expressed skepticism about the success of the 4680 battery, suggesting Musk tends to overpromise timelines.

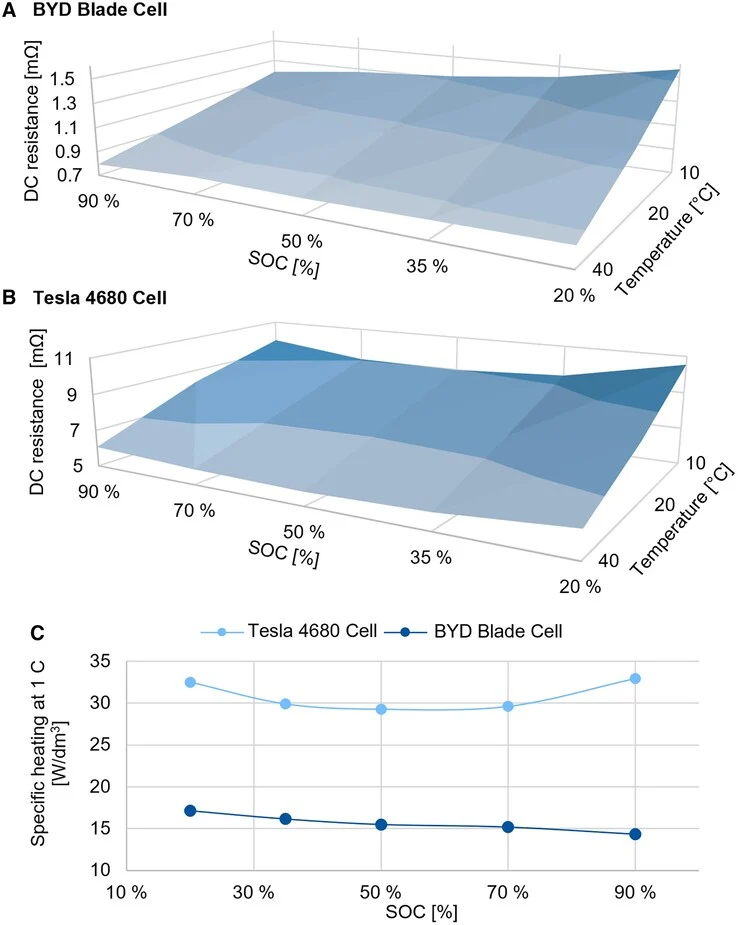

4. A comparison of Tesla’s 4680 battery and BYD’s Blade cell revealed significant differences in thermal efficiency and resistance behavior under charging conditions.

5. Tesla’s 4680 battery may face challenges with thermal design, impacting charging efficiency and performance in vehicles like the Cybertruck.

When Elon Musk let go of Tesla’s battery lead, Drew Baglino, last spring, he also removed the manager for the 4680 cell production facilities at Giga Texas.

Drew wanted to work on the 4680 battery as Elon Musk had outlined during Battery Day in 2020, aiming for a 50% cost reduction compared to Tesla’s traditional batteries.

However, this process was taking longer than expected. Elon thought that if Tesla couldn’t achieve any cost cuts by the year’s end, it would be better to source 4680 batteries from suppliers like LG, which has a factory in Arizona that produces 4680 cells using a more advanced manufacturing method.

Developments in Production

Since that time, Tesla has announced it has figured out a dry cathode production method that makes the 4680 battery costs much more competitive and has begun integrating these new cells into the Cybertruck.

Yet, according to CATL’s chairman, Robin Zeng, the 4680 battery Musk envisioned “is going to fail and never be successful.” He even reportedly demonstrated why, leaving Musk “silent.”

Zeng believes that Musk tends to overpromise. “Maybe something needs five years. But he says two years. I definitely asked him why. He told me he wanted to motivate people,” Zeng stated.

Battery Design Strategies

The two largest EV battery manufacturers, CATL and BYD, prefer to make iterative upgrades to their battery designs and chemistry, always aiming for compatibility with mass production. This method has proven effective so far, even as they work on successful solid-state or sodium-ion battery projects.

A new teardown of a BYD Blade and a Tesla 4680 battery cell suggests that Zeng might have a valid point. Research led by Jonas Gorsch from RWTH Aachen University found that the prismatic BYD cell has double the thermal efficiency of Tesla’s 4680 battery.

The team dissected both cells to examine their housing structures, dimensions, thermal characteristics, and the precise material makeup and costs of their electrodes, revealing some fascinating differences and similarities, including laser welding.

Performance Comparisons

Tesla’s 4680 battery provided an energy density of 241 Wh/kg, compared to the 160 Wh/kg of the Blade cell. This difference makes sense since the Tesla battery is nickel-based, while the BYD battery utilizes the more economical LFP chemistry.

However, when charging current was applied, researchers observed an anomaly with Tesla’s 4680 battery cell: the resistance of the 4680 cell increases at high State of Charge (SOC) values, especially in cooler temperatures, while the BYD Blade cell’s resistance decreases with higher SOCs. This could be due to increased charge transfer resistance at the anode’s surface from high lithium concentration, as such resistances usually rise with SOC. This phenomenon requires further exploration since a rise in total cell resistance at higher SOC is unusual, given that the cathode’s charge transfer typically decreases, offsetting the anode resistance increase.

Consequently, Tesla’s 4680 battery cell produced double the heat that needs to be dissipated per volume under the same charging load. In summary, the BYD cell is “more favorable for designing a cooling strategy for fast charging,” according to the researchers.

This less efficient thermal design might clarify the odd charging curve of the Model Y fitted with the first version of Tesla’s 4680 battery, as well as the ongoing slow charging issues with the Cybertruck, even though it uses the next-generation cells referred to as Cybercells.

Tesla did attempt to resolve the Cybertruck’s charging curve with an over-the-air update; however, tests at Tesla’s new 325 kW V4 Superchargers revealed little change in charging time. The thermal inefficiencies of the 4680 battery could be part of the issue, as suggested by the study.

Get the 80A Tesla Gen 2 Wall Connector with 24′ cable on Amazon.

Leave a Reply