Key Takeaways

1. Thermalright began as an air cooler company and is expanding into mini PCs, maintaining a focus on cooling solutions.

2. The upcoming mini PCs will start at around $2,000 and feature high-performance components, including an AMD Ryzen AI MAX+ 395 and 128 GB of unified RAM.

3. Unique design features include CNC-ed parts, compact custom liquid cooling systems, and a front display showing temperature and system information.

4. Performance testing shows that the liquid-cooled mini PC reached 89° C under load, indicating effective cooling within thermal limits.

5. A prototype mini PC with a distinct red and black design is showcased, featuring innovative cooling and upgradeable components, though mass production is uncertain.

Thermalright started by selling air coolers at reasonable prices and later moved into other areas. Right now, their main focus is still on air coolers, but they also offer AIOs, PC cases, and, as seen at Computex this year, they are trying to break into the mini PC market with compact, powerful systems that feature custom liquid cooling.

Hands-On Experience

The team from LinusTechTips (ShortCircuit) and Gamers Nexus had a chance to check out some of the new mini PCs at Thermalright’s booth. Stephen from Gamers Nexus mentioned that Thermalright plans to launch its first mini PCs at prices that are competitive with other brands like Minisforum. LTT pointed out a starting price of around $2,000 for a model with an AMD Ryzen AI MAX+ 395, equipped with 128 GB of unified RAM, allocating 96 GB for the CPU and 32 GB for the Radeon RX 8060S dGPU.

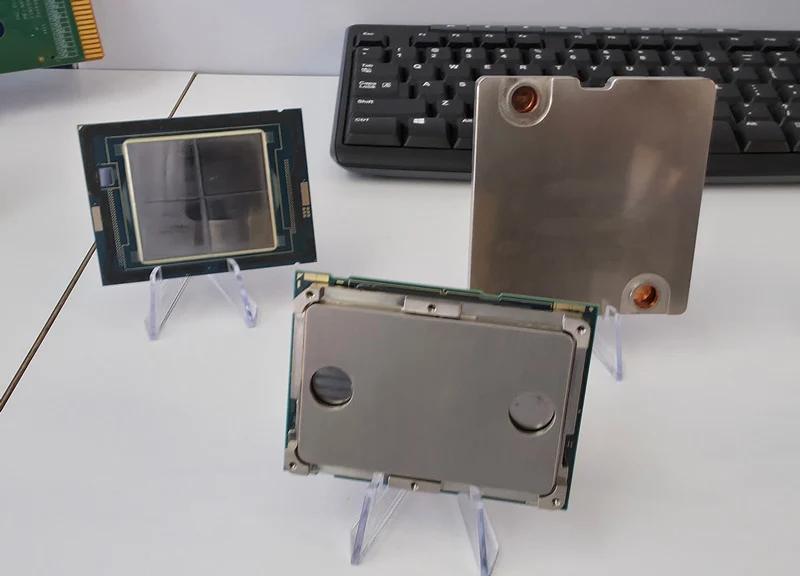

Unique Features

Some may think this pricing isn’t very competitive, but Thermalright is including special features. For instance, the chassis has CNC-ed parts, such as the removable bottom plate from one of the models shown in the LTT video. More importantly, these designs come with compact custom liquid coolers. Lastly, there’s a small front display that shows temperature and other useful information.

Performance Insights

Are these liquid-cooled options really efficient in such tiny form-factors? The model featured in the LTT video reached 89° C when all CPU cores were pushed to their limits for an extended period, indicating some thermal constraints. However, this isn’t too bad considering TJMax is 95° C, and it remains to be seen if fan noise is lower than with standard air cooling. To improve airflow and potentially lower temperatures, Thermalright offers a longer case that accommodates a larger liquid cooler.

Compact Options

There was also a smaller case shown at the booth, likely set to use lower-tier processors. Other specifications seen in the LTT video include a MediaTek Wi-Fi 7 card, dual M.2 slots for SSDs, and a front panel that features a full-size SD card reader, a USB4, and two USB-A 3.2 Gen 2 ports.

Prototype Design

In addition, Thermalright displayed a prototype mini PC with a striking red and black frame, reminiscent of Cyberpunk 2077. This model features an innovative liquid cooling system above a Ryzen 7 8845HS, plus easily accessible SSD and SO-DIMM slots for future upgrades. While it may not go into mass production, things could shift if there’s enough interest from fans.

Source:

Link