Key Takeaways

1. Micron Technology is the first memory manufacturer to produce DDR5 modules using sixth-generation 10nm-class DRAM with EUV lithography, improving speed and efficiency.

2. The new 16 GB DDR5 modules can reach speeds up to 9200MT/s, a 15% performance increase, along with over a 20% reduction in power consumption.

3. Micron’s advancements will benefit various sectors, including data centers, mobile devices, and automotive systems, enhancing performance and energy efficiency.

4. Major collaborations with AMD and Intel are underway, focusing on validating Micron’s new DDR5 products for improved server and AI performance.

5. Micron’s 1γ DRAM chips are currently manufactured in Japan, with plans to expand EUV lithography production in Japan and Taiwan.

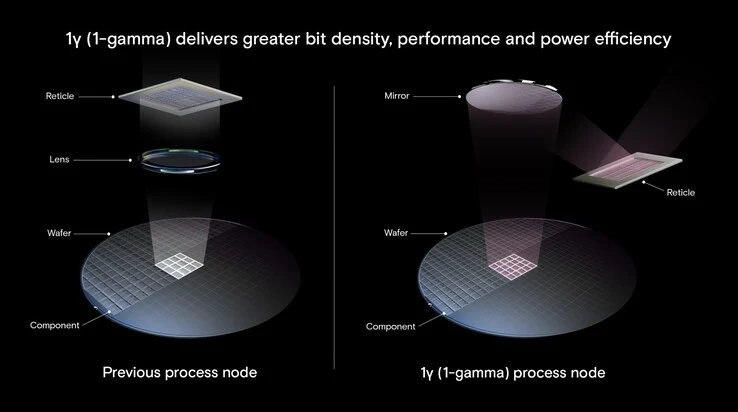

Micron Technology has recently achieved a significant milestone by becoming the first memory manufacturer to send out sample versions of DDR5 modules created using its latest sixth-generation 10nm-class DRAM node, referred to as 1γ (1-gamma). This marks the first instance where Micron employs EUV (extreme ultraviolet) lithography in its production process. This advancement leads to notable improvements in speed, energy efficiency, and production yields.

Enhanced Performance

With this innovative technique, Micron’s 16 GB DDR5 integrated circuits can hit speeds of up to 9200MT/s. This represents a commendable 15 percent increase in performance compared to the earlier 1β (1-beta) generation, all the while achieving over a 20 percent reduction in power usage. Moreover, the new production method enhances bit density by more than 30 percent, which might help lower costs as the manufacturing process becomes more established.

Advancing AI Technology

Scott DeBoer, who serves as Micron’s executive vice president and chief technology & products officer, stated, “Micron’s know-how in creating unique DRAM technologies, together with our strategic application of EUV lithography, has led to a strong lineup of advanced 1γ-based memory products ready to advance the AI ecosystem.”

Micron aims to utilize the 1γ node for a wide array of future memory solutions, such as:

– Data center applications: This will provide up to a 15 percent boost in performance while enhancing energy efficiency to manage power use and heat.

– Mobile devices: LPDDR5X versions will facilitate state-of-the-art AI features directly on smartphones or tablets.

– Automotive systems: LPDDR5X running at speeds of up to 9600MT/s will enhance capacity, improve product longevity, and offer better performance.

Collaborations with Major Players

Both AMD and Intel have commenced validation of Micron’s new DDR5 offerings. Amit Goel, Corporate VP of Server Platform Solutions Engineering at AMD, emphasized how this partnership fits with the company’s initiatives to continuously refine its EPYC processors and consumer-focused hardware. On the other hand, Dr. Dimitrios Ziakas from Intel pointed out the benefits of improved energy efficiency and higher density, which will positively impact server settings and AI-focused PCs.

Currently, Micron manufactures these 1γ DRAM chips at its plants in Japan, where the organization installed its first EUV lithography system in 2024. As production scales up, Micron intends to deploy more EUV machinery at its facilities in both Japan and Taiwan.

Source:

Link