Key Takeaways

1. Keynote Speaker and Event Details: Casey Putsch will discuss car design with composite materials at the 25th Annual Composites Conference and Exhibition in Novi, Michigan, from September 3-5, 2025.

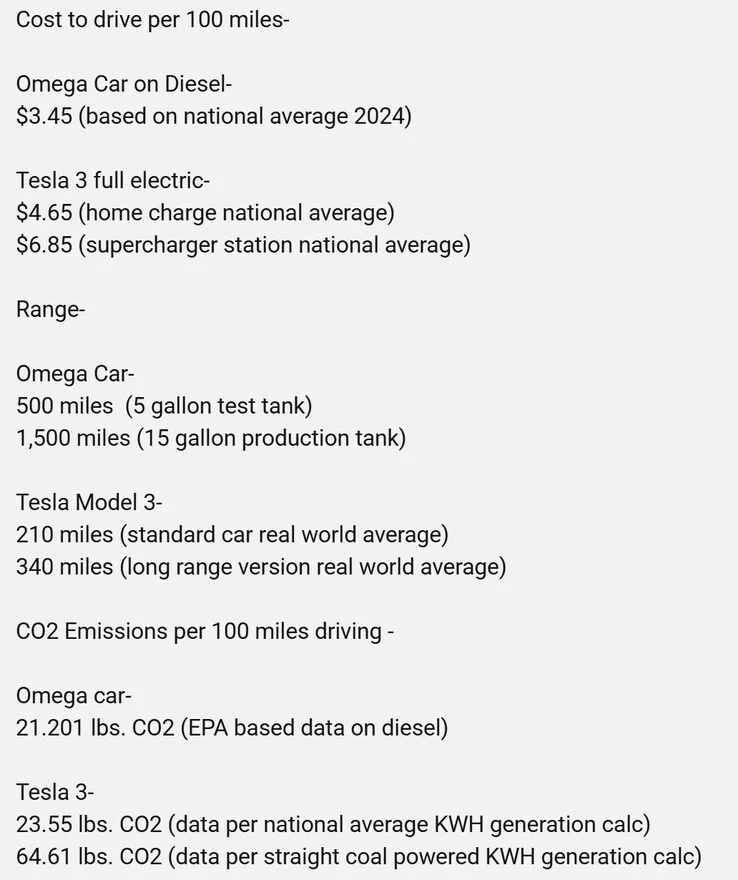

2. Carbon Emissions in Car Production: Car manufacturing, including electric vehicles like the Tesla Model 3, produces significant CO2 emissions, emphasizing the need for environmentally friendly alternatives.

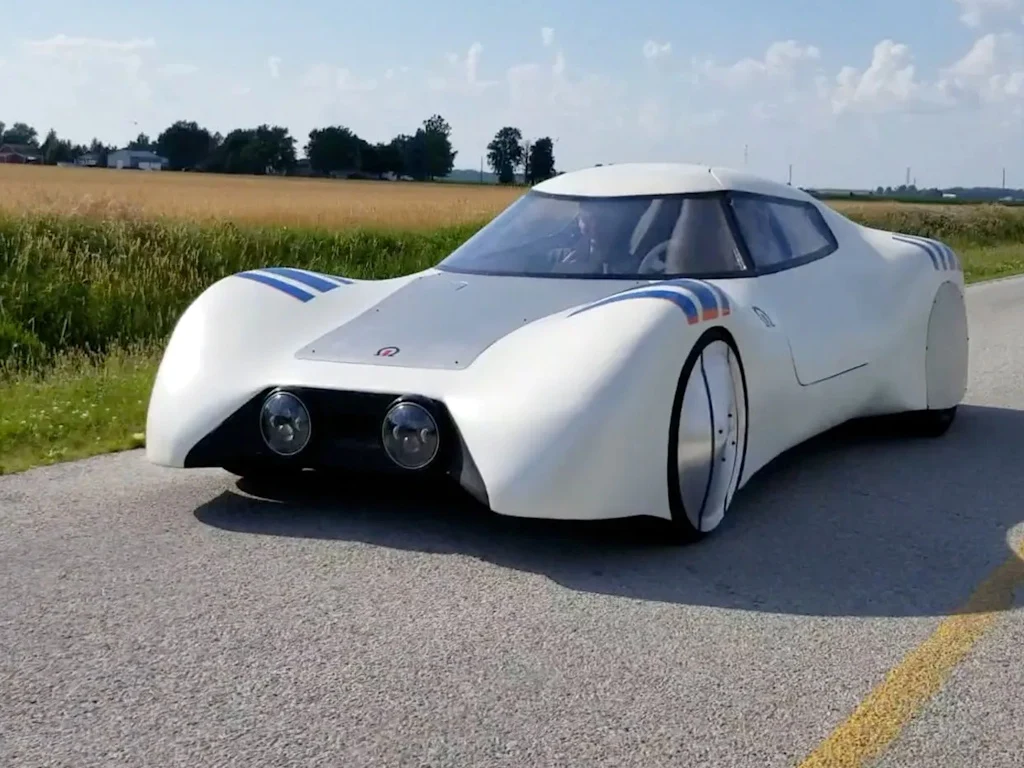

3. Opportunities for Improvement: Putsch highlights that outdated design practices lead to poor material choices, and his prototype Omega showcases how advanced composites can create efficient and eco-friendly vehicles.

4. Benefits of the Omega Prototype: The Omega achieves over 100 mpg, has lower emissions than the Tesla Model 3, and is lighter due to recyclable composite materials, reducing manufacturing carbon footprints.

5. Aerodynamic Features for Efficiency: The Omega uses innovative design elements, such as digital cameras instead of mirrors and a Kammback shape, to improve aerodynamics and fuel efficiency.

Keynote speaker Casey Putsch will talk about how to think about designing cars with composite materials at the 25th Annual Composites Conference and Exhibition. This event will be hosted by the Society of Plastics Engineers in Novi, Michigan, from September 3-5, 2025. People can sign up to attend the ACCE 2025 for a fee of $200 to $800 to discover the newest composite materials for vehicles.

Carbon Emissions in Car Manufacturing

Car production and usage release a lot of carbon emissions. For instance, Tesla thinks that the CO2 produced by its Model 3/Y cars ranges from 72 to 116 grams per mile. This figure doesn’t take into account the CO2 from other activities like designing, testing, and selling. Electric vehicles (EVs) can emit less CO2 compared to traditional combustion engine (ICE) cars, especially when looking at popular models such as the Tesla Model 3 in contrast to the Toyota RAV4.

Opportunities for Improvement

Putsch has pointed out that outdated design ideas and market pressures have resulted in subpar material selections and vehicle designs that could see major enhancements. He has developed a prototype called the Omega, a two-seater that utilizes advanced composite materials, which “could help in the mass production of chic and affordable vehicles that are energy-efficient and kinder to the environment, even when using standard internal combustion engine technology.”

The Advantages of the Omega

The Omega achieves over 100 mpg with a conventional Volkswagen turbo diesel engine, while also producing lower energy generation emissions compared to the Tesla Model 3. The carbon emissions from manufacturing and recycling at the end of the vehicle’s life are also reduced due to the use of lighter composite materials that can be recycled more easily than fiberglass or carbon fiber.

Moreover, the Omega doesn’t require a battery pack weighing around 1,000 pounds like the Tesla. Intelligent design choices help to lower the vehicle’s weight, such as using seat cushions that are directly attached to the rear bulkhead.

Aerodynamics and Fuel Efficiency

Additionally, the Omega features effective aerodynamic designs to enhance fuel efficiency. It incorporates digital cameras instead of side mirrors for better visibility, and its wheel covers are designed as non-rotating, non-vented ‘pizza pans’ to facilitate smoother airflow. The rear of the vehicle employs a Kammback design to minimize drag.

Source:

Link

Leave a Reply