Embark on your 3D printing journey with exclusive deals on the Kingroon KLP1 3D Printer. For a limited time, from November 1st to December 30th, seize the opportunity to purchase this innovative printer at the flash price of $339, down from the original price of $379. Use the code “KLP1” during checkout to enjoy an additional discount of $40, making this cutting-edge technology even more accessible. This special offer is valid across various warehouses, including the US, EU, AU, and CN.

Exclusive Discounts on AliExpress

But that’s not all, from November 18th to December 30th, you can get the device at a discounted rate on AliExpress. Utilize the code “KLP1010” to unlock a discount on the flash price, reducing it to $339. This exclusive deal applies to warehouses in RU, KR, and CN.

Special Discount on Kingroon Filament

Enhance your printing experience further by taking advantage of a special discount on Kingroon Filament. Apply the code “10TWH58T” from November 6th to November 30th to enjoy exclusive savings on the premium filament, ensuring that your 3D prints achieve the highest quality and precision. Act fast and seize these limited-time offers to elevate your 3D printing endeavors with Kingroon technology.

Kingroon KLP1 3D Printer

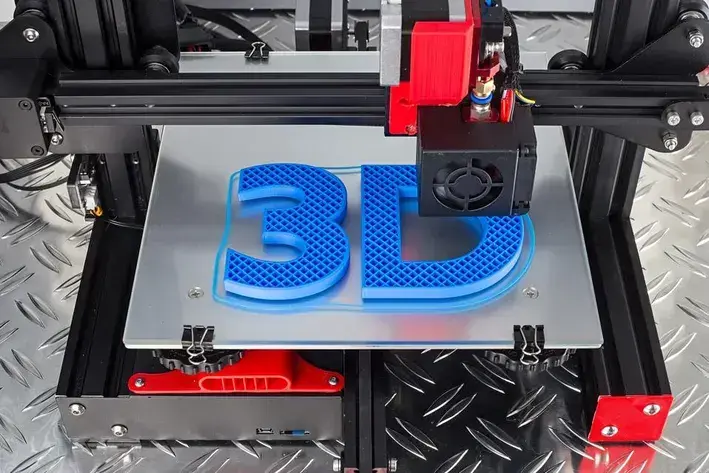

The Kingroon KLP1 3D Printer is a cutting-edge device that combines advanced features with user-friendly design, making it an ideal choice for DIY enthusiasts and those seeking personalized 3D printing experiences. Let’s delve into the key features of this remarkable printer.

All-in-One Klipper Mainboard

The KLP1 boasts a powerful mainboard with pre-installed Klipper firmware, eliminating the need for an external Raspberry Pi. This feature provides a seamless and efficient printing experience, meeting diverse DIY needs and enabling users to develop personalized settings effortlessly.

All-Metal Hotend with Ceramic Heating Core

Featuring an all-metal hotend with a ceramic heating core, the KLP1 opens up a world of possibilities for material options. From traditional materials like PLA, ABS, PETG, and TPU to high-temperature materials such as nylon and CF, the KLP1 ensures better, faster, and more stable heating for a wider range of applications.

Automatic Leveling with Precision

The auto bed leveling system on the KLP1 comes with ±0.025mm precision, ensuring a perfectly leveled bed for every print. With its new bed structure, the accuracy of ±0.025mm guarantees consistent and reliable results, making calibration a hassle-free process.

High-Speed Printing with Dual Modes

Experience high-quality printing with reduced waiting time, thanks to the KLP1’s impressive printing speed of 500mm/s and acceleration of 10000mm/s². Choose between the normal mode at 300mm/s or the high-speed mode at 500mm/s, offering flexibility based on your specific printing requirements.

CoreXY Structure with Linear Rail Guides

The CoreXY structure, combined with linear rail guides on the X and Y axes, ensures the KLP1 delivers accuracy, speed, and durability during rapid movements. The linear rails provide superior stability and precision compared to traditional V-wheels.

Powerful Extrusion with 5:1 Gear Ratio

Equipped with a 5:1 gear ratio, all-metal components, a 9500 rings 5015 bearing fan, CHC hotend, and smart microprocessors, the KLP1’s extruder delivers powerful and consistent extrusion. The printer supports a maximum temperature of 300°C, coupled with a high-speed ball fan for rapid cooling and efficient model molding.

Latest Slicing Settings with OrcaSlicer

The KLP1 comes with the latest slicing software – OrcaSlicer, offering a user-friendly interface for seamless slicing operations. This ensures optimal print quality and enhances the overall printing experience.

PEI Magnetic Platform for Easy Model Removal

Utilize the PEI Magnetic platform to simplify the removal of printed models effortlessly. This feature adds convenience to the 3D printing process, allowing users to easily detach completed prints.

Wifi/Ethernet Connectivity for Remote Control

With support for Wifi and Ethernet connectivity, the KLP1 enables direct printer operation from computers, mobile phones, tablets, and other devices. This feature provides users with the flexibility to control the printer remotely, enhancing accessibility and ease of use.

Vibration Compensation for Quality Prints

The KLP1 is equipped with vibration compensation technology, reducing the impact of vibrations during the printing process. This results in higher-quality 3D prints and an overall improved printing experience.

The Kingroon KLP1 3D Printer stands out as a versatile and reliable choice for 3D printing enthusiasts, offering a range of features that prioritize precision, speed, and ease of use. Whether you’re a seasoned hobbyist or a newcomer to 3D printing, the KLP1’s innovative design and advanced capabilities make it a standout option in the world of 3D printing technology.

Kingroon PLA Plus 3D Printer Filament

Kingroon PLA Plus 3D Printer Filament, precision-crafted for superior performance. With a dimensional accuracy of +/- 0.03 mm, this filament ensures hassle-free printing with no plugs or air bubbles. Experience efficient and clog-free printing with neatly arranged, evenly spaced wires. Boasting 1.5 times the fluidity and 1 times the impact resistance of ordinary PLA, Kingroon PLA Plus guarantees smooth output and reduced material blockage. Its low melting point (155°C-170°C) and recommended printing temperature (180°C-200°C) make it eco-friendly, energy-efficient, and FDA food contact compliant.