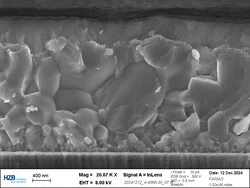

Each film is an astonishing 2 μm thick and consists of four layers piled together. These layers include a CIGS crystal layer made from copper, indium, gallium, and selenium, an intermediate layer of aluminium-doped zinc oxide, a perovskite layer, and finally a contact layer at the base.

Comparison with Traditional Solar Modules

On the other hand, the active layer in a solar module that you can buy commercially must be at least a hundred times thicker. This leads to a lot more material being used, which increases weight and limits flexibility for other possible uses.

Efficiency Improvements

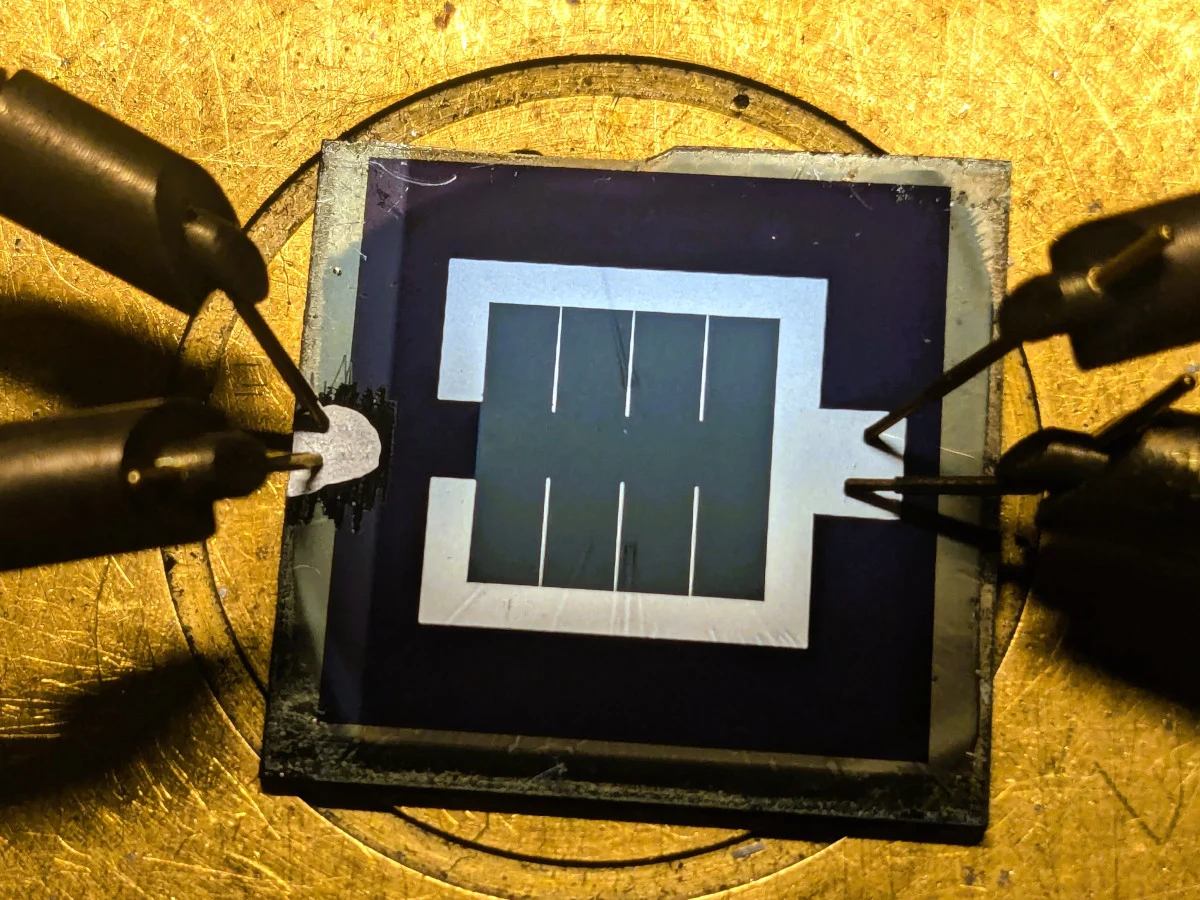

By enhancing the contact surfaces between the two parts of a tandem solar cell, which must allow light to pass through with minimal interference, scientists managed to boost the cell’s efficiency to 24.6%. The Fraunhofer Institute for Solar Energy Systems ISE has confirmed this measurement through a specific testing method.

Future Potential

The team at Helmholtz-Zentrum believes that they can push the efficiency beyond 30%. If they succeed, this thin-film approach would rank among the top tandem solar cells, but require much less material to produce.

Despite this exciting potential, we still don’t know how well the ultra-thin film will hold up over time. Perovskite-based solar modules—especially those that are highly efficient—tend to lose efficiency significantly when exposed to moisture and sunlight.

Production Challenges

Moreover, the manufacturing process needs to be greatly simplified before these thin-film cells can be used in real-life situations. Applying layers that are less than 1 μm thick requires a cluster system with vacuum and transfer chambers, indicating that this technology is still quite far from the $300 balcony solar panels we see today.

Source:

Link

Leave a Reply