Key Takeaways

1. Sodium-ion batteries show promising performance, comparable to lithium iron phosphate (LFP) batteries in various tests.

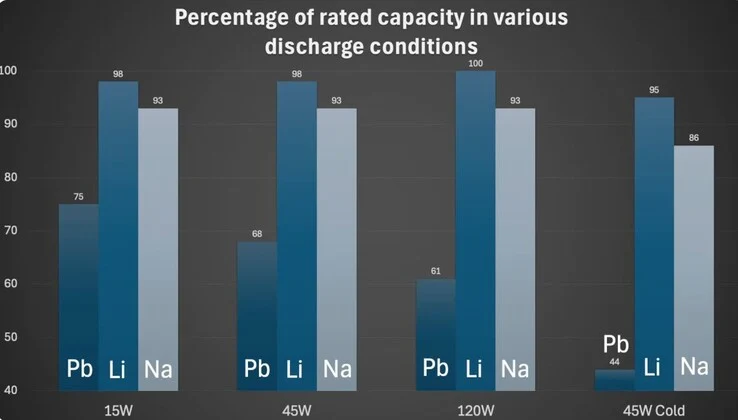

2. In high discharge load tests, sodium-ion batteries deliver around 93% of their rated capacity, outperforming lead-acid batteries significantly.

3. Sodium-ion batteries excel in cold weather, producing higher capacity compared to lead-acid and LFP batteries at low temperatures.

4. Sodium is more abundant and cheaper than lithium, making sodium-ion batteries a potential future alternative for energy storage.

5. Despite current advantages, LFP batteries are still cheaper due to economies of scale, but sodium-ion technology is gaining attention for home storage solutions.

Much has been talked about sodium-ion batteries and how they could become a popular substitute for lithium-based battery technologies. Sodium is much easier to find compared to its alternatives and it also works quite well, as shown by a real-world charge and discharge test that highlights its performance against other common battery types.

Testing Methodology

In a YouTube video by Alex Hibbert Originals, a sodium-ion battery is put to the test alongside a lithium iron phosphate (LFP) battery and a lead-acid battery under various conditions. The outcomes are quite encouraging. In the initial test, the lead-acid battery only provides about 3Ah of its 4Ah rated capacity when it is discharged steadily at 15W. Meanwhile, the 2Ah LFP battery does remarkably well, with 1.94Ah being utilized; the 4Ah sodium-ion battery doesn’t quite match the LFP battery but still delivers 3.7Ah.

High Discharge Load Performance

When the discharge load is increased to 45W, similar results are observed. At an effective 1C discharge rate, the lead-acid battery only manages 2.7Ah, or roughly 68% of its rated 4Ah capacity. On the other hand, the LFP battery supplies a complete 2Ah, even at a 2C discharge rate, while the sodium-ion battery again delivers 3.7Ah, which is about 93% of its rated capacity.

At a 120W discharge load, the lead-acid battery does even worse, providing just 2.4Ah—61% of its capacity—under an effective 2C discharge rate. The 2Ah LFP battery shines again, yielding an impressive 2.3Ah, likely due to the tough 4C discharge rate. The sodium-ion battery keeps up its performance, drawing 3.694Ah despite the increased discharge rate.

Cold Weather Testing

In an additional test, all three batteries were discharged in extremely cold conditions (-22°C) with a 45W power draw. The lead-acid battery produced 1.755Ah, the 2Ah LFP battery provided 1.89Ah, and the 4Ah sodium-ion battery yielded 3.42Ah.

To sum it up, sodium-ion batteries seem to perform comparably to their LFP equivalents. Throughout all three standard temperature tests, the LFP battery essentially delivers 100% of its rated capacity, even when discharged at rates above 4C. The sodium-ion battery falls slightly short at around 93% of capacity. Meanwhile, the lead-acid battery, which is generally considered less effective, only manages to achieve about 75% of capacity, even at a lenient 0.3C discharge rate.

Given that sodium-ion batteries are made from much cheaper materials compared to LFP batteries, they could represent the future of energy storage, especially in applications like home storage where the lower energy density isn’t a major concern. It’s worth mentioning, though, that LFP batteries are still cheaper at the moment due to economies of scale.

Source:

Link