Key Takeaways

1. Tesla is increasing the construction of charging stations using a new, cost-effective foundation solution.

2. The new installation method uses polypropylene housing, allowing faster setup without concrete foundations.

3. This approach reduces costs by up to 70% compared to competitors and speeds up the installation process.

4. The method also allows for quicker repairs of damaged Supercharger stations, supporting Tesla’s commitment to rapid restoration.

5. The innovative solution contributes to reducing the CO2 footprint of the charging infrastructure.

Tesla is ramping up the construction of its charging stations and the repair or installation of Supercharger piles using a new foundation solution.

Prefabricated Units and Their Benefits

Previously, the company used a Prefabricated Supercharger Units (PSU) approach, where they shipped ready-made piles with all the electrical wiring on a concrete slab. This method allowed Tesla to set up Supercharger stations in just days rather than weeks, and it was significantly cheaper—up to 70% less than competitors. This cost-effectiveness has helped Tesla win numerous federal and state contracts for public charging infrastructure subsidies.

Faster and More Efficient Installations

Now, Tesla aims to speed up the process even further. As Max de Zegher from Tesla emphasizes, the electric vehicle charging infrastructure must grow 30 times larger. To achieve this, the company has developed a new method for installing or replacing Supercharger stalls that eliminates the need for concrete foundations or for transporting prefab units from its Buffalo, NY factory.

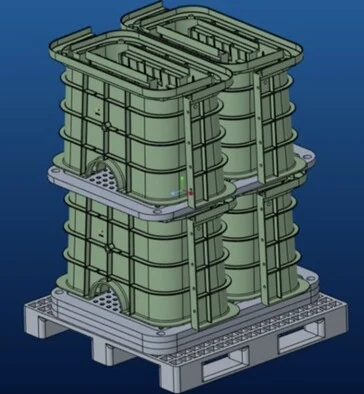

The new solution involves a polypropylene housing that a single person can easily place in a dugout and then secure with gravel. According to de Zegher, this approach “reduces C02 footprint, is faster, and reduces cost.”

Responding to Damage Promptly

This innovative installation method could also facilitate quicker repairs for damaged piles. With Elon Musk’s increasing political activism, there has been a rise in vandalism and arson against Tesla’s vehicles and charging stations. Tesla has committed to replacing any burned or damaged Supercharger stations within 48 hours, and they have successfully met this goal so far.

The polypropylene housing filled with local gravel may prove useful not just for new installations but also for repairing or replacing piles, depending on the level of damage sustained by Tesla’s charging stations.

Source:

Link